We are an ECP / casing external packer supplier.

The two most common forms are the production or test packer and the inflatable packer.

Production or test packers may be set in cased holes and inflatable packers are used in open or cased holes.

The expansion of the latter is accomplished by pumping a fluid into a bladder, in much the same fashion as a balloon, but having more robust construction.

◆Main function:

Hydraulic inflation Packer is mainly used for oil and gas well cementing operation for all kinds of down hole isolation .It plays an important role to improve the quality of well cementing operation. The tool is not only easy to be operated but also can be used to oil and gas wells with many kinds of down hole conditions. Inflatable element varies with hole diameter and down hole differential pressure automatically. Valve system can make ECP set i the perfect position safely.It’s confirmed that External Casing Packer is an important tool for well completion .

◆Product Standard:

SY/T5404-2002

◆Structure

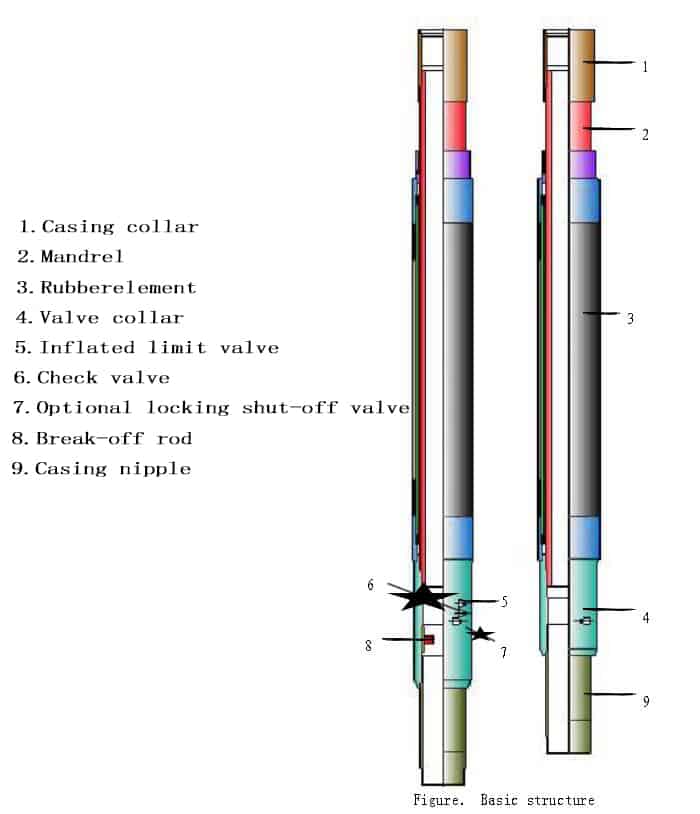

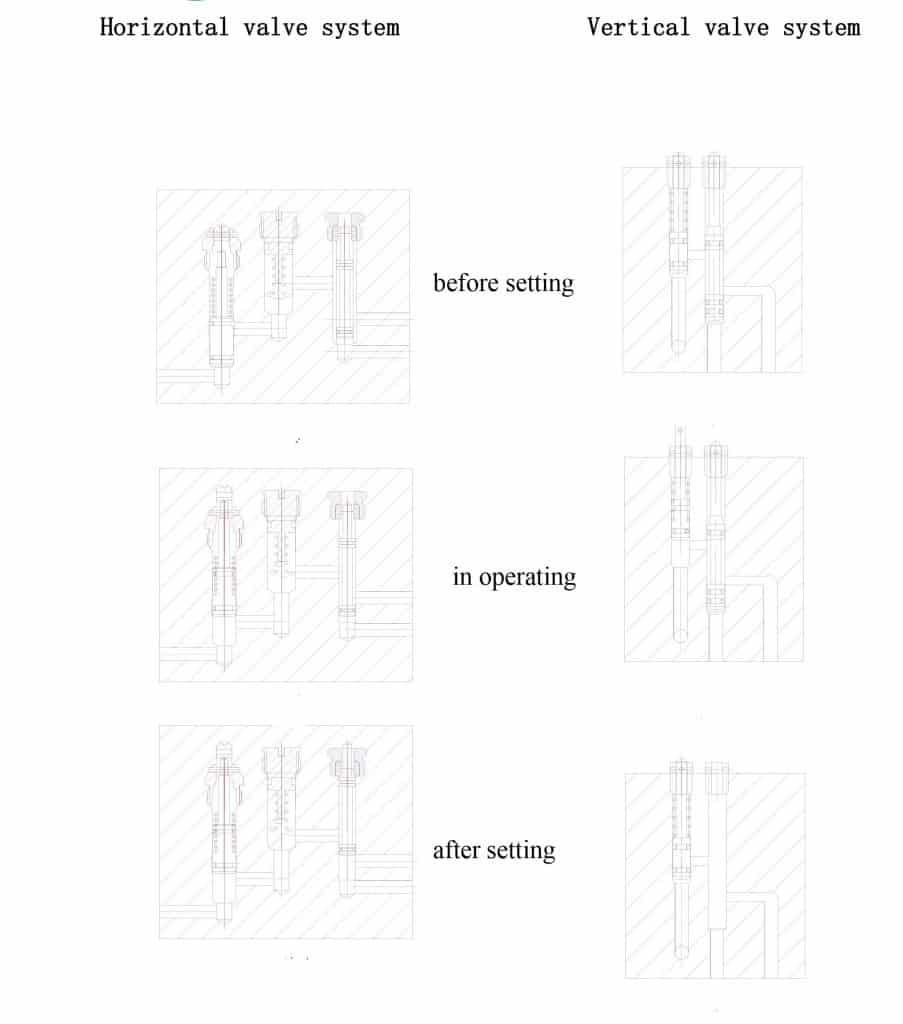

JC hydraulic inflation Packer is made up of mandrel, rubber element ,casing collar,casing nipple and inflation mechanism. Inflation mechanism consists of horizontal valve system or vertical valve system. Horizontal valve system consists of three valves making inflation, Vertical valve system consists of two valves making inflation.

Casing external packer Features

- Continuous one 一 piece mandrel

- Identical specifications to casing

- H2S and CO2 resistant

- Easily replaceable valve components

- Easily re-pinned

- Available in special clearance

- Available in high temperature

◆Principle of work

The inflation process Wiper plug break the optional break-off rods off through the casing and mandrel to the blind ram pressure applied to the casing forces the inflation fluid through the valve collar screen to the shear-pinned locking shut-off valve .

The size of the shear pin, installed from outside of the tool before it is run, determines the casing pressure at which the tool inflates.

Using different size of pins. Multiple ECPs can be set individually without prematurely inflating anyone of them.

After the fluid passes through the shut-off valve, opens the spring-loaded check valve, passes through the inflate limit valve. And inflates the steel-reinforced rubber element .

The inflated limit valve is also shear-pinned at the surface to close when the inflation pressure within the element reaches a preset pressure.

Once the packer is set, a substantial reduction in casing pressure will close the locking shut-off valve and provide extra protection for the element from any subsequent changes in casing pressure.

The accompanied down hole working can’t shorten the service life of packers.

◆Technical parameter:

(1) Mode

(2) Model Specification Parameter

| ModelJCModel | Diameter (mm) | Max OD (mm) | ID (mm) | Total length (mm) | Length of rubber element (mm) | Hole diameter (mm) | Thread connection |

| JC48 | 48 | 78 | 2130~2740 | 915~1520 | 84~132 | 1.9TBG | |

| JC60 | 60 | 89 | 52 | 2130~2740 | 915~1520 | 95~147 | 2 3 /8″TBG |

| JC73 | 73 | 102 | 62 | 2620~12000 | 950~11000 | 109~168 | 2 7 /8″TBG |

| JC89 | 89 | 114 | 76 | 2620~12000 | 950~11000 | 121~188 | 3 1 /2″TBG |

| JC102 | 102 | 133 | 89 | 2680~12000 | 950~11000 | 141~220 | 4″TBG |

| JC114 | 114 | 146 | 97 | 2660~12000 | 950~11000 | 155~241 | 4 1 /2″LCSG |

| JC127 | 127 | 148 | 108 | 2680~12000 | 950~11000 | 157~245 | 5″LCSG |

| JC140 | 140 | 178 | 121 | 3000~12000 | 950~11000 | 188~294 | 5 1 /2″LCSG |

| JC140 | 140 | 190 | 121 | 3000~12000 | 950~11000 | 201~314 | 5 1/2″LCSG |

| JC178 | 178 | 206 | 155 | 3000~12000 | 950~11000 | 216~337 | 7″LCSG |

| JC245 | 245 | 286 | 220 | 3150~12000 | 950~11000 | 303~472 | 9 5 /8″LCSG |

| JC273 | 273 | 324 | 250 | 3200~12000 | 950~11000 | 343~535 | 10 3/4″CSG |

| JC298 | 298 | 349 | 273 | 3400~12000 | 950~11000 | 365~576 | 11 3 /4″CSG |

(3) Mandrel strength: Mandrel is a joint of the same easing used in the casing program.

(4) The pressure to open locking shut-off valve:10MPa,15MPa, 20MPa, 25MPa or according to the customer’s requirement .

(5) The pressure to close inflated limit valve:7-10Mpa or according to the customer’s requirement .Don’t change it by yourself.

(6) ECP set in the well bore at the maximum temperature 150℃.

(7) Storage condition : temperature -20℃~35℃, maximum humidity 80%,store time 2 years.

◆ Operation manual:

(1) According to different purposes, select the packer set position correctly.It’s necessary for the packer to be set in a regular well bore and dense formation.

(2) Calculate the annulus pressure packer which is set on the well and make sure the maximum pressure is available or not .

(3) According to the maximum circulation pressure, determine the pressure of optional locking shut-off valve shear pin , Pp.

(4) Determine the maximum application pressure from gauge Pg :

Pg = Pp + ΔPs + Pa

Notes : Pg – the maximum construction pressure from gauge, MPa.

ΔPs – the pressure in packer set position, MPa.

Pa – the accessory pressure, generally Pa = 3~4MPa .

Fig.3. PACKER LIMITING DIFFERENTIAL

(5) Apply program

The inflated pressure arise slowly. Stress gauge of the cement truck shows Pg. The optional locking shut-off pin is sheared. Keep the pressure for 3-5 min. to inflate the packer completely, then reduce the pressure to zero quickly. Every valve is closed, and the inflation process is completed.

◆Operation manual

(1) Transport

The packer is packed with wood box. Carry carefully , make the package undamaged

(2) Inspection on wellsite

- When arriving at wellsite, put the packer to smooth land.

- Check the exterior of thread ,rubber element and valve system.

- Check the break-off rods, stick mustn’t be plugged in mandrel.

- Check it the pressure of optional locking shut-off valve shear pin is identical to the label-marks or not ,if not, change it .

(3) Running Packer

- Don’t hit the Packer and don’t pull it on the ground ,while putting the Packer to drillfloor.

- Clean the pin and box threads ,smear sealing greasy in it .

- Don’t use tongs at the marked place ,while making threads up.

- Use centralizers up and down ECP to fit the casing and to prevent rubber element from cutting by the sides of the borehole.

- Control the setting pressure exactly.

- Take detailed record of the packer using condition.