What is liner hanger system?

Liner Hanger is a tool/system that is used to hang a liner in a oil well. Liner is similar to casing, but it is not run to the full depth of the well as casing. JC Petro Liner hanger systems could be mechanical or hydraulic, premium or standard, rotating or non-rotating, conventional or expandable and pocket slip.

JC Petro is the Liner Hanger System supplier with API Certificate from China.We can also offer oversea sales service and have succeed project cases.

JC Petro has been providing specialized drilling and cementing tools to the oil and gas industry from founding. Our liner hanger systems are designed to work in every well condition and has been accepted by our clients.

What is the con structure of Liner Hanger System?

JC Petro liner hanger system (also called liner system) includes a liner hanger, polished bore receptacle (PBR) and a liner-top packer,Sealing assembly,Setting Tool. Liner hanger systems can be mechanical or hydraulic, premium or standard, rotating or non-rotating, conventional or expandable and pocket slip. t can be configured for rotation, reaming or drill down capabilities. Each of the systems is used in different applications.

Our product portfolio includes liner packers, liner hangers, setting tools and accessories, surface cementing equipment, down hole cementing accessories such as port collars and stage cementing tools and tieback equipment.

The main parts of the Liner Hanger System

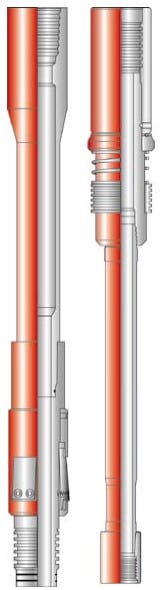

SSX-A hydraulic liner hanger :

The SSX-A is hydraulic liner hanger features with double cones,double cylinders and double-row slips,set by applying pressure through the run-in string.A setting ball is circulated or a ball seat built into the landing collar.Applied pressure acts on the internal piston and moves slips up the cone to the set position.

Product Features:

- 1.To be set by hydraulically,which is designed for in all types of wells.

- 2.Can set easily with two different setting mechanism.

- 3.Working with setting-set carrier,the SSX-A is suitable for applications in horizontal or high-deveated wells.

- 4.The piston sealing element is made of nitrile/fluorine rubber for higher pressure and temperature ratings.

- 5.Main parts are fabricated with high-strength alloy steel providing high burst/collapse resistance.

Specifications (mm):13-3/8”×9-5/8”,9-5/8”×7”, 7”×5”

Rated Load(T):180、120 、80

Sealing Capacity (MPa):>25

Body Max O.D.(mm):308、215 、148

Body Min I.D.(mm):220、155、108

Top Packer Liner Hanger

Features

- 1,A liner top packer is incorporated into a liner hanger to seal liner/casing overlap after setting the liner.

- 2,The packer is set by compression.

- 3,Ppacker element has superior capacity to resist aeid, alkali,oil and high temperature.

- 4.The packer is capable of holding 5,000psi differential pressure.

Specifications(mm):9-5/8” / 7” /5”

I.D.(mm):φ302/φ208/φ146

Polished Bore Receptacle

Mated with tie-back assembly,it can tieback the liner to the top of well and act as efficiency sealing.The polished bore receptacle(PRB)is a highly machined component with a polished bore.

Features

- 1、High quality surface finish on the inner seal bore for optimum sealing property.

- 2、The top end is chamfered for easy entry.

- 3、Manufactured to strict roundness and wall thickness tolerances,giving optimum burst and collapse pressure ratings.

Specifications,mm:9-5/8”/7”

Length,mm;3500 /3100/2880

I.D.,mm:φ260/φ187/φ133

Sealing Assembly

The Sealing assembly comprises shell and pack off bushing and is used to seal the annular clearance between polished nipple and liner hanger body so as to build pressure after the ball reaches the landing collar,preventing current from passing through upwaed. There are sinistral-threads on the top of connecting setting tool.

FEATURES

- 1. The pack off bushing can be brought out of well,saving much drill out time.

- 2. “W”sealing rings are used to obtain two-side sealing.The sealing effect is better and it’s sealing caoacity is more than 25Mpa.

- 3.With centralized block on body,it makes the hanger center easily.

Setting Tool

The setting tools are used to run,set,and manipulate liners,and isdesigned to bear weight of liners after setting.The roller-bearing race and reverse-nut provide the most reliable system for releasing drill pipe from liners.

Features

1,The thrust bearing ensures ;positive release from liner top.

2,A longer polished nipple helps to judge if the sinistral-threads ware released or not .

3,With a traoezoidal-threaded joint,the setting tool is convenient to disassemble and carry.

4,Drill pipe threed at top.

Technical Parameters:

Trapezoidal-threads Joint :IF4-1/2” IF 3-1/2”

Min I.D.,mm:φ76 φ52

Sealing Capacity,Mpa:35

Carrying Capacity of Supporting Sleeve,t:20

Pump down Plug

The Pump down Plug has a series of four rubber wipers of different sizes. Various sizes allow the plug to wipe the inside of tool joints and liner setting string. It performs well in highly-deviated and horizontal setting string. The plug is designed to seat securely into the wiper plug.

The two plugs then move as one down the liner to the landing collar.

Technical Parameters

Specifications,mm:9-7/8“/ 7“/5”

Max O.D.of Guide Head,mm:φ63/ φ58/φ45

Length of Pumpdown Plug,mm:295/355/295

Liner Wiper Plug

The Liner Wiper Plug may be shear-pinned on the bottom of the setting tool. The conjunction with pump down plug keeps mud to be separated from cement and removes the cement from the inside of the liner.

Technical Parameters

Specifications,mm:9-7/8“ / 7“/ 5“

Shearing Pressure,Mpa:13-14

Back-pressure,Mpa:25

Any liner hanger system design work will involve many parameters and its components.Such as: Pressure, temperature, depth, stresses, well geometry.These elements will impact on the liner hanger system costs and lead times. It is better to let us know your details each inquiry.

Generally speaking, one liner hanger system and its installation cost is less than 1% of the total well cost. If purchasing from us. additional FREE local service is also available.