Reamer Shoe

Reamer shoe overcome wellbore obstructions and guide the casing or liner to total depth. Our reamer shoe designs use an eccentric guide nose to negotiate ledges and other obstructions while its integrated cutting structures simultaneously ream out tight spots.

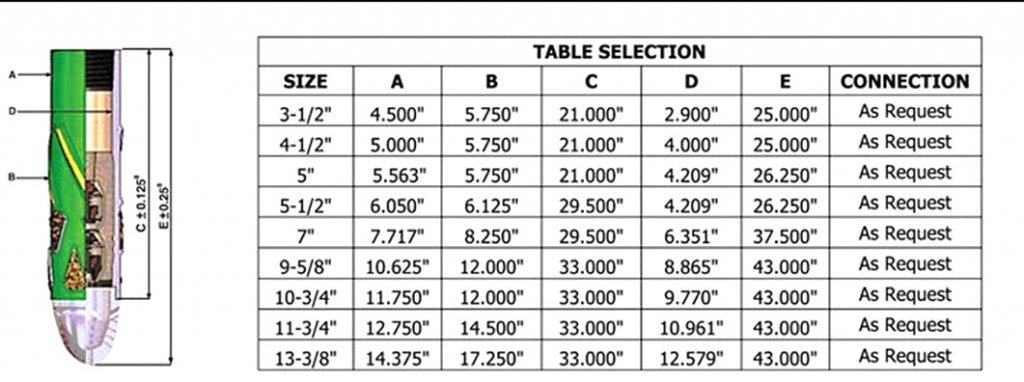

Size:3 1/2″ to 26″

WhatsApp: +86 158 0546 5460

Specification

The smooth body design has eliminated potential areas which can trap solids and cuttings.

Description

Reamer Shoe is designed for various sizes of casing and borehole. This product is applicable for large diameter casing string with either hydraulic or mechanically set hangers. The Reamer Shoe is made in compliance with API RP 10 F. The nose area is constructed using high quality material and can be easily drill by both PDC and Tri-cone rock bit.

The eccentric guide nose climbs ledges and negotiates obstructions while the cutting structure reams out tight spots or obstruction in the wellbore. Compatible with all cementing product,casing and liner hanger assemblies, our Reamer Shoe provides highly effective protection- against unexpected or anticipated casing and liner running problems, and has been specifically designed for potentially difficult wellbore conditions such as swelling shales, ledges and washed out areas of wellbore.

Features

- 1.For use with and without rotation

- 2.Specially built to fit any casing and hole size combinations

- 3. PDC drillable

- 4.Reamer shoes are equipped standard with an enclosed down-jet nose, aggressive cutting

- 5.Supplied in a P-110 casing grade

- 6. Our reamer Shoe connections are available in all types of API and Premium connections depending on customer request, as well as with flush connections.

Application

The reamer shoe is designed for use with rotation-resistant casing or liners. This tool is recommended for use in wells where difficulties may exist while running casing. We utilize various configurations of tungsten carbide depending on the type of obstruction that is anticipated.

- Can be used in either vertical or horizontal wells

- Can be used with or without float valves

- Regularly used with float collars to fulfill the role of guiding casing to a planned depth and serving as the primary valve during the cementing process

- Designed to solve multiple issues such as: sections that are closed by swelling, eyes of key, landslides and accumulation of cuts on the low side of the hole in horizontal wells

- Allow liners to reach their total depth as they are run down hole with hangers (that can be rotated) once introduced

- Available in either a drillable or non-drillable design

- Designed to accommodate the different geometry of bore holes, formation pressures, formation stability and any preferences of the operator

- API Standard Casing Reamer Shoe

- Tough durable profiled cement nose

- Fitted with High flow phenolic float valve tested in excess of API test procedures

- 5,000 & 10,000 psi Valves Available

- Double Valve Option Available

- Auto fill Option Available

- New and Improved cementing process for valve retention

- Cement tested to 5000 & 10,000psi

- Material: P-110, K55, J55, N80

- Thread Type: BTC, STC, LTC, NEW VAM or BLANK THREAD &Customized

- Size Available: 5 1/2″, 6 5/8″, 7″, 8 5/8″, 9 5/8″, 10 3/4″, 11 3/4″, 13 3/8″, 16″, 18 5/8″, 20″ reamer shoe

- PDC drillable

As a China Reamer Shoe Manufacturer, our Service:

Pre-Sales Service

Inquiry and consulting support.

Sample testing support.

View our Factory.We would like to introduce more product details to you.

After-Sales Service

Training how to install and use the machine.

Engineers available to service machinery overseas.