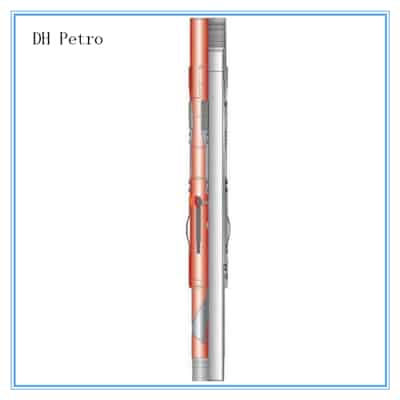

Mechanical Liner Hanger

It is a mechanical hanger with single cone and single slip. A “J” shaped groove was machined into the body. The hanging can be realized by lifting up and rotating down. The structure is simple, suitable for vertical wells and shallow wells.

The liner hanger can be set by picking up and lowering the drill string.

- Size: 7″ * 9 5/8″ , 5″ * 7″

WhatsApp: +86 158 0546 5460

Mechanical Liner Hanger Parameter

| Specifications (in) | 7″ * 9 5/8″ 177.8mm *244.5mm | 5″ * 7″ 127 mm*177.8mm |

| Rated Load (KN) | 120 | 50 |

| Up Distance (m) | > 0.04 | > 0.04 |

| Right Hand Angle | > 35 | > 35 |

| Casing Wall Thickness (mm) | 10.03 11.05 11.99 | 9.19 10.36 11.51 |

| Casing Weight (kg/m) | 59.52 64.73 69.94 | 38.69 43.15 47.62 |

| Body Max O.D.(mm) | 215 | 152 |

| Body Max I.D.(mm) | 155 | 108 |

Description

JC mechanical liner hanger is designed with one row cone and one row slips, manufactured a J slot on the body. Set by right-hand rotation.

Features

- 1. Large bypass channels in the cone increase annular flow area.

- 2. The J slot design prevent the hanger from prematirely setting during deployment.

- 3. Depending on the friction between bow spring and the wall of upper casing to set.

- 4. Set by right hand rotation.

Specifications

- 1:φ244.5mmxφ177.8mm(9 5/8”x7”)

- 2:φ177.8mm×φ127mm(7”×5”)

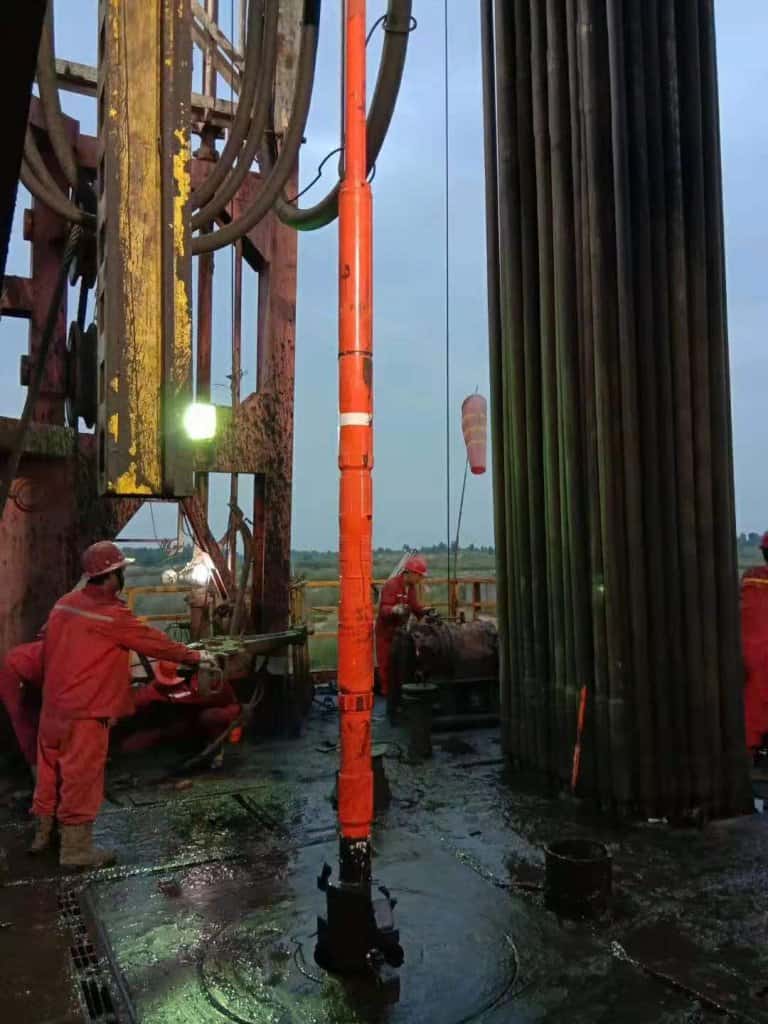

Mechanical Liner Hanger is used for hanging lower liner which needs cementing.

The liner hanger can be set by picking up and lowering the drill string.

What is the size of liner hanger you can manufacture?

From 4″ to 20″.

What is the structure of the liner hanger system?

Mechanical and hydraulic liner hangers systems are mainly composed of: liner hanger assembly, feeding tool assembly, sealing assembly, ball seat assembly, rubber plug, floating collar, floating shoes, core pipe coupling and others.

What is the difference between liner and casing?

A casing string that does not extend to the top of the wellbore, but instead is anchored or suspended from inside the bottom of the previous casing string.

There is no difference between the casing joints themselves. To save casing, however, additional tools and risk are involved.

What is the liner hanger using principle?

When run the liner to the designed depth,set the liner hanger,release the setting tools and finish cementing.

After bumping the plug,pull the drill pipe,the claws on the setting tools expand out and act on the upper surface of the polished bore receptacle sleeve,lower down the drill pipe,shear the pins and the rubber sleeves expand to seal the annuls between upper casing and the polished bore receptacle.