Cementing Plug

Conventional & Non Rotating Cement Plug

Top & bottom cement plugs

Size:2-3/8“ to 20″

Description

The cementing plug is used to separate the cement slurry from the mud. It can prevent the mud from blending into the cement slurry to influece the cementing quality.

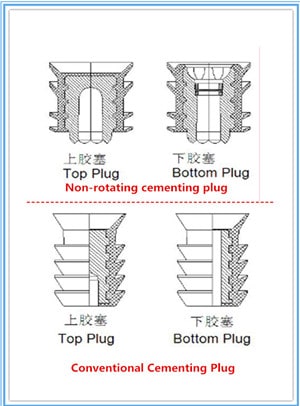

Two types of cementing plugs are typically used on a cementing operation: Conventional cementing plug and Non Rotating Cementing Plug

Conventional cementing plug product image

Non Rotating Cementing Plug product image

Conventional cementing plug and Non Rotating Cementing Plug has Top Plug and Bottom plug.

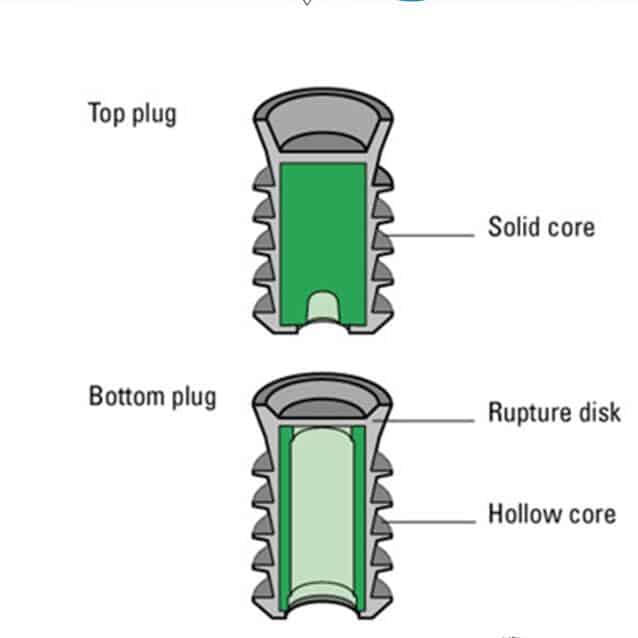

Top Plugs:

The Top Cementing Plug is designed to exert continuous pressure on the casing wall. The core is made of special materials such as Plastic, Aluminium or Phenolic depending on the application and well conditions. The tapered base fits the cavity of the top plug initiating a positive seal. A solid rubber top plug is also available.

Bottom Plugs:

Like the Top Cementing Plug, the fins and tail section provide positive wiping action. Fins also serve as a seal while cementing. The core of the bottom plug also made of special materials such as Plastic, Aluminium or Phenolic depending on the application and well conditions. A rubber diaphragm at the top of the plug ruptures after the plug is seated allowing cement to flow through.

Specification

| Casing Size | Casing weight range | Wiper Fin | O.D | |

| in | mm | in | mm | in |

| 4 1/2″ | 14.14-17.26 | 9.50-11.60 | 110 | 4.331 |

| 5″ | 17.11-35.86 | 11.50-24.10 | 122 | 4.803 |

| 5 1/2″ | 20.83-39.88 | 14.00-26.80 | 135 | 5.315 |

| 7″ | 25.30-56.55 | 17.00-38.00 | 170 | 6.693 |

| 7 5/8″ | 35.72-63.69 | 24.00-42.00 | 185 | 7.283 |

| 9 5/8″ | 53.57-79.62 | 36.00-53.50 | 235 | 9.252 |

| 10 3/4″ | 60.27-97.77 | 40.50-65.70 | 260 | 10.236 |

| 13 3/8″ | 71.43-107.15 | 48.00-72.00 | 333 | 13.110 |

| 20″ | 139.89-197.93 | 94.00-133.00 | 498 | 19.606 |

Our cementing plugs are specially designed with a positive wiping action to ensure that the casing is clean.

The top cementing plugs is designed to exert continuous pressure on the casing wall.

The fins and tail section of bottom plugs provide positive wiping action. Fins also serve as a seal while cementing.

Rotating cement plug are manufactured of graded rubber that is fused upon a composite or Aluminum core.

This top plug can be used when dual plug system is not required and Bottom cementing plug can be used when dual plug system is required. These plugs are completely PDC drillable.

Operating range of temperature with Aluminum core is up to 200 degree Fahrenheit. Plug can be ordered for higher operating temperature and operation in either synthetic or mud fluids.

The Non-Rotating Top and Bottom Cementing Plugs significantly reduce the drill out time, thereby resulting in cost saving.

The top plug has a solid body that provides positive indication of contact with the landing collar and bottom plug through an increase in pump pressure.It follows plug to displace cement, latches into the upper end of the bottom after latching these provide anti-rotational feature to eliminate rotation during drilling and save drill out time. No metal parts are used, therefore the plug are completely PDC drillable

The Bottom Plug separates the cement from drill mud, and features a rubber diaphragm, which is opened once the plug has landed and latched into the Anti-Rotational Float Collar. The bottom plug is launched ahead of the cement slurry to minimize contamination by fluids inside the casing prior to cementing. A diaphragm in the plug body ruptures to allow the cement slurry to pass through after the plug reaches the landing collar

Conventional Top and Bottom Plug is also available can be drilled out with PDC and conventional drill bit.

Structure:

The core is made of aluminum or phenolic resins, depending on the application and well conditions.

The plug is made of high performance materials such as rubbers or phenolic resins.

How does it work?

Generally, Top plug and bottom plug are matched to use. Before cementing, put into bottom plug firstly, scrape and clean the wall of hole by pump. After pump plug, increase the pressure to 2~4 MPa,hold and broken the rubber film, circulation is established.

And then,start to inject the cement, put into top plug, pumping, increase the pressure, finished cementing.

The Non-Rotating Top & Bottom Cementing Plugs are designed to decrease drill out time.

When the drilling fluid make the bottom plug move into the end, raised plum flower petal of the bottom plug’s lower end engaging with the hollow plum flower petal of float collar’s upper end.

Using Method:

Place bottom plug before injecting cement, and pump the scrape to clean the well-wall. After all is set, build the pressure of 2-4MPa till the rubber diaphragm is broken, and thus circulation is formed. Then inject the cement, place the top plug, pump, set the pressure, and well cementation comes to an end.

The diferent of each cement plug.

Anti – rotating cement plug,When cementing isolate the cement slurry and mud to prevent the cement slurry from infiltrating into the mud and affecting the cementing quality.

Conventional cementing plug can be divided into two types according to its use: upper cementing plug and lower cementing plug.(rubber plug, also known as rubber plug, can be used for single plug cementing)

The upper cement slurry is separated from the slurry to prevent the cement slurry from being polluted, and the cement slurry is replaced into the annulus at the same time.

Lower cement slurry and slurry are separated to prevent cement slurry from being polluted. There are shear pins inside the cement slurry that can be opened to provide a channel for cement slurry.

Our rubber plug conforms to API and China oil and gas industry standards, and is also a best-selling product of our company, which is well received by users.

Anti – rotating cement plug can be engaged automatically when pressing for the slurry. When the drill bit drilling the cementing rubber plug, the rubber plug will no longer rotate together with the drill bit, thus greatly improving its crushing efficiency and eliminating the hidden danger of oil well.