Liner Hanger With Packer

We are a Liner Hanger With Packer manufacturer. Different packer liner hanger size and grade materials can be supplied.If you have Liner Hanger With Packer inquiry or tender,welcome contact us.

When oilfiled cementing in waiting to be solidified, the high-pressure oil, gas and water invade the cement slurry that has not been fully solidified to form a channel of flow.After the cementing, the sealing quality of the overlapping section is poor. No cement at all causes the formation of oil, gas and water to penetrate into the casing or the fluid in the well to invade the formation.

Running the liner hanger with packer is an effective measure to ensure the sealing quality of overlapping sections.

After the packer is set, an isolation layer can be formed between the outer casing and the tail pipe. It can prevent the migration of oil, gas and water.

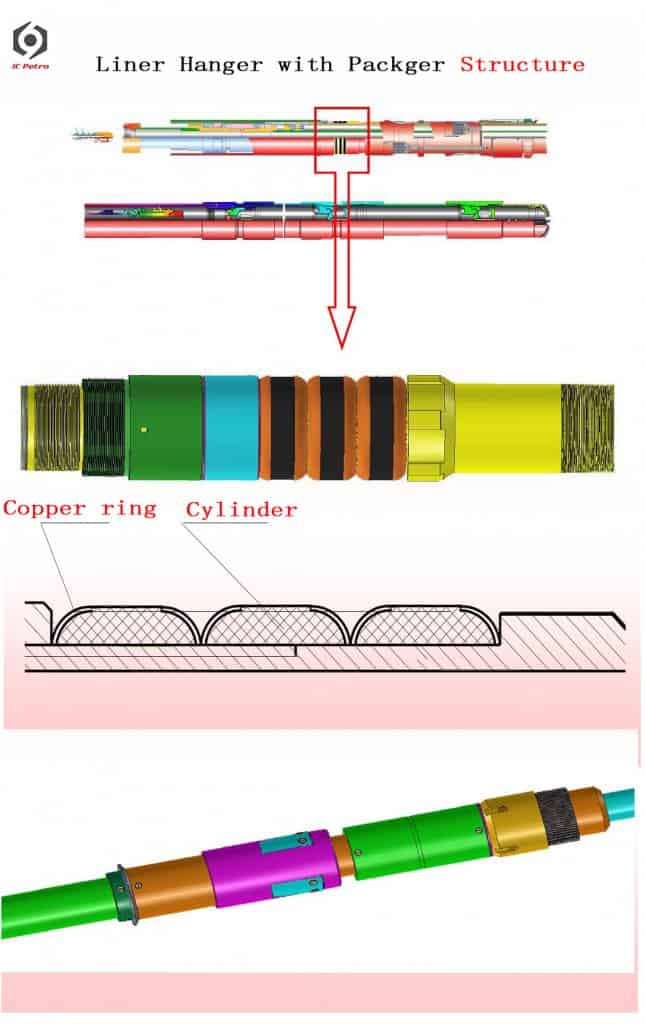

Liner Hanger With Packer Structure

Operating Principle

- 1-The packer is set by mechanical method.

- 2-After the liner hanger pipe has been lowered into the design position,As per the regular procedure to sit, buckle, inject cement, replace slurry, and touch pressure.

- 3-The tool is lifted up, the setting mechanism extends from the hanger, and sits on the top of the return cylinder.

- 4-Press a certain weight and cut off the fixing pin.

- 5-The rubber cylinder is squeezed and deformed under pressure.It forms a seal in the annulus of the outer casing and the tail pipe.

Features:

- 1.Combination of free fall packer and liner hanger, the Liner Hanger with Packer performs double functions – sealing and liner hanging.

- 2.Rubber sleeve has good acid resistant, alkali-resistant and oil resistant properties as well as high temperature resistance.

- 3.Bearing pressure difference is more than 35MPa.

- 4.Easy back off for the running tools: some tons of load added can realize back off with right hand rotation.

- 5.The sealed ram can be pulled out along with running tools, therefore no drill out is required.

Liner Hanger Packer Main Parameter

| Specification | A | B | C |

| Seat pressure, t | 30– 50 | 30– 50 | 30– 50 |

| Rated load, t | 160 | 120 | 160 |

| Load carrying capacity of load support sleeve, t | 16 | 16 | 16 |

| Sealing capacity, MPa | 25 | 25 | 25 |

| Hydraulic cylinder shear nail shear pressure, MPa | 7–8 | 7–8 | 7–8 |

| Shearing pressure of ball shear pin, MPa | 16-17 | 16-17 | 16-17 |

| Shear nail shear pressure of tail pipe rubber plug, MPa | 12 | 12 | 12 |

| Casing steel grade | N80 Pll0 | N80 Pll0 | N80 Pll0 |

| Casing wall thickness (mm) | 10. 03, 11. 05, 11. 99 | 10. 03, 11. 05, 11. 99 | 10. 03, 11. 05, 11. 99 |

| Casing nominal weight (m / kg) | 59. 52, 64. 73, 69. 94 | 59. 52, 64. 73, 69. 94 | 59. 52, 64. 73, 69. 94 |

| Maximum outer diameter of the body (mm) | 215 | |

| Inner body diameter (mm) | 155 | |

| Total length of drill rod rubber plug (mm) | 332 | |

| Copper ball diameter (mm) | S Φ45/42 | |

| Length of return barrel (mm) | 2800 | |

| Simple diameter of back connection (mm) | Φ187 | |

| Lifting short section upper joint Thread type | 410 (NC50) | |

| Overflow area | casing wall thickness (mm) | Before/after mounting, cm2 |

| Overflow area | 10.03 | 65/35 |

| Overflow area | 11.05 | 57/31 |

| Overflow area | 11.99 | 51/28 |

Liner Hanger Packer Project Case

The Exsisted Problem

The failure of the liner hanger rubber Cylinder caused the well completion failure.

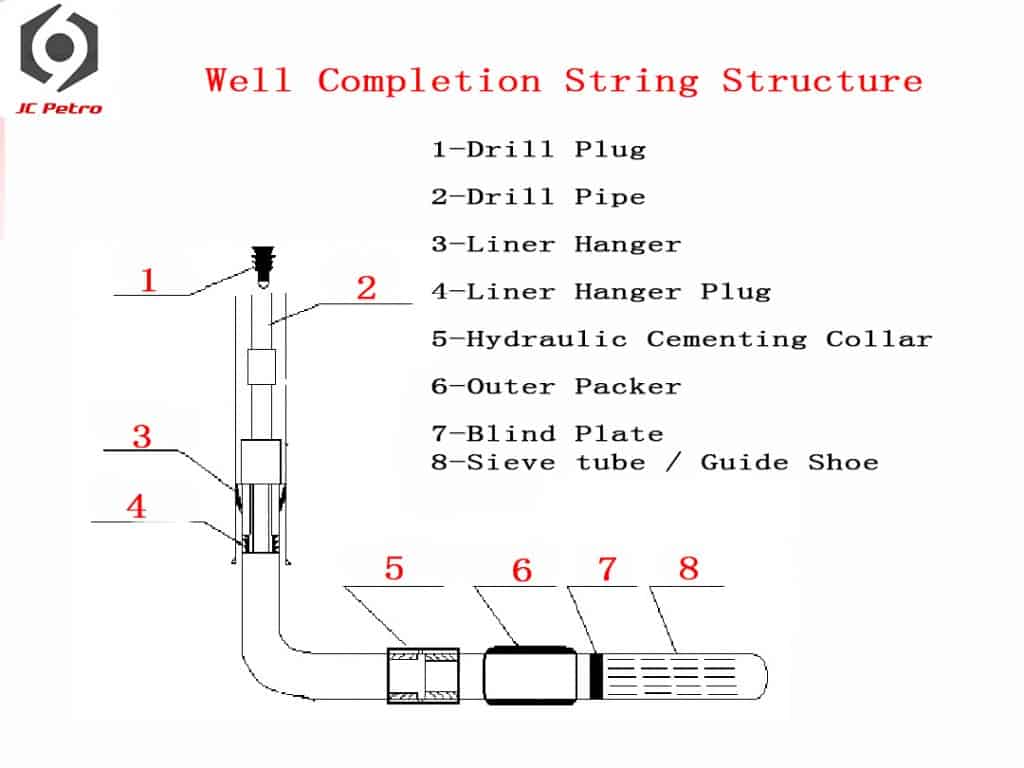

The New solution

Use a packer liner hanger to connect the sieve tube, then connect it to the cementing well

The Test

In the test, the centralizer was welded to the packer body so that the outer diameter was greater than 218mm.

Weld two rectangular centralizers to the outer surface of the isolation sleeve. So that the thickness on one side is greater than the thickness on the other side (3mm thick, then 9mm).

The diameter of the two centering blocks is 222.5mm.

The inner diameter of the housing is 244.4 inches.

After sealing set, pressure up to 25Mpa and observe the seal.

Conclusion

From the above test process and test data, this test is successful. It meets the requirements of sealing and sealing in an eccentric state.The sealing pressure of 25 Mpa can meet the requirements of customers’ horizontal well cementing.

Well condition

- Production well Horizontal well

- Well depth 1539m

- Well declination 92 degree

- 9 5/8 inch casing depth: 1179m

- 5-1/2 liner hanger length 35m

- Sieve Tube: 352m

- Weight of drilling tool 38 ton

- Hanger float weight 20 ton

- The depth of the liner hanger in well is 1122

- Sitting and hanging upside down is normal

- Set down and press 25 tons

- Pressure test 6Mpa, stabilized voltage

- Test pressure 12MPa, Stabilized voltage

- Back to cementing

If you have any inquiries of liner hangers, Contact us freely.

Tel & WhatsApp: +86 158 0546 5460 Email: sale@greenenergyoilfieldservices.com